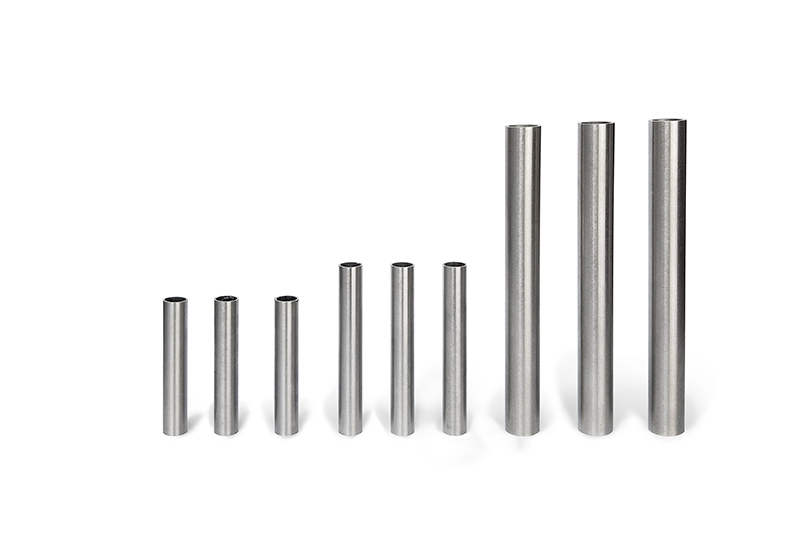

PRODUCT INTRODUCTION

Stainless steel polished tubes possess high corrosion resistance and decorative properties, and have been widely adopted in medical instruments, food processing equipment, tableware, and kitchenware. Stainless steel utensils must exhibit corrosion resistance, bright appearance, and hygienic cleanliness, with surfaces that must not contain substances toxic to humans. Therefore, specific requirements are imposed on the surface treatment during manufacturing; polishing stainless steel tubes aims to completely remove harmful surface substances. Common polishing methods include electrolytic polishing and chemical polishing.

PRODUCT FEATURES

By visual inspection, the brightness level of the polished surface is classified into 5 levels:

Level 1: There is a white oxide film on the surface;

Level 2: Slightly shiny, unable to see the outline clearly;

Level 3: Good brightness, with visible contours;

Level 4: The surface is bright and the contour is clearly visible (equivalent to the surface quality of electrochemical polishing);

Level 5: Mirror like glossy polishing.

APPLICATION AREA

Mechanical manufacturing, household appliances, pressure vessels, structural pipe fabrication, architectural decoration, chemical equipment, nuclear power, home appliances, catering kitchenware, elevators, solar energy, metal products, containers, automotive applications, precision electronics, rail transit, sanitary ware, food machinery.

PRODUCTION STRENGTH